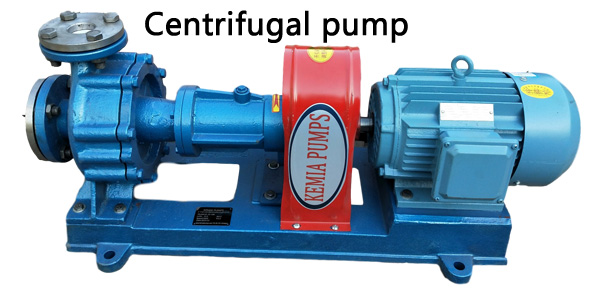

One, the centrifugal pump over current components

Centrifugal pump flow components are: suction room, impeller, pressure out of the chamber three parts.

Impeller chamber is the core of pump, and also the core of flow components.

The work done by the pump impeller on the liquid increases its energy.

Impellers are divided into three categories according to the direction of liquid outflow:

(1) The liquid in a radial impeller (centrifugal impeller) flows out of the impeller in the direction perpendicular to the axis.

(2) The liquid in the oblique flow impeller (mixed flow impeller) flows out of the impeller along the direction of the axis tilt.

(3) The direction of liquid flow in the axial flow impeller is parallel to the axis.

The impeller is divided into two types according to the suction method:

(1) Single-suction impeller (i.e., impeller suction liquid from one side).

(2) Double-suction impeller (i.e., impeller suction liquid from both sides).

The impellers are divided into three types according to the cover:

(1) Enclosed impeller.

(2) Open impeller.

(3) Semi-open impeller.

The enclosed impeller is widely used, the aforementioned single-suction impeller and double-suction impeller belong to this form.

Hot Oil Pump China

Two, centrifugal pump working principle

The working principle of centrifugal pump is: centrifugal pump so can send water out is due to centrifugal force.

Before the pump is working, the pump body and the inlet pipe must be filled with water into a vacuum state. When the impeller rotates quickly, the blade makes the water rotate quickly. The rotating water flies away from the impeller under the action of centrifugal force.

The water in the hydrogens under atmospheric pressure (or water pressure) through the network pressure into the inlet tube.

This circulates unceasingly, may realize the continuous pumping.

It is worth mentioning here is: before the start of the centrifugal pump shell must be filled with water, can start, otherwise it will cause pump body heat, vibration, water output reduction, damage to the pump (referred to as “cavitation”) cause equipment accidents!

There are many kinds of centrifugal pump, classification methods are common in the following ways: 1, according to the impeller suction way: single suction type centrifugal pump double suction type centrifugal pump.

2, according to the number of impeller divided into: single-stage centrifugal pump multistage centrifugal pump.

3, according to the impeller structure: open impeller centrifugal pump semi-open impeller centrifugal pump closed impeller centrifugal pump.

4, according to the working pressure: low pressure centrifugal pump medium pressure centrifugal pump high pressure centrifugal pump.

5, according to the pump shaft position: horizontal centrifugal pump/vertical chemical pump.

Three, the following several important centrifugal pump performance curve.

Performance parameters such as flow Q head H axis power N speed N efficiency have a certain relationship.

The relation between them is expressed by a curve, which is called the performance curve of the pump.

The relationship and mutual restraint between the performance parameters of the pump: the first prerequisite is the frontal speed of the pump.

Pump performance curve has three main curves: flow – lift curve, flow – power curve, flow – efficiency curve.

1. Flow-lift characteristic curve

It is the basic performance curve of the centrifugal pump.

Centrifugal pump with specific speed less than 80 has the characteristics of rising and falling (both middle convex, both sides of the bend), called hump performance curve.

The centrifugal pump with specific speed between 80 ~ 150 has a flat performance curve.

The centrifugal pump with more than 150 revolutions has a steep-drop performance curve.

Generally speaking, when the flow hour, the head is high, as the flow increase, the head gradually decreases.

2. Flow-power curve

The shaft power increases with the flow rate. When the flow rate Q=0, the corresponding shaft power is not equal to zero but a certain value (about 60% of the normal operation).

This power is mainly consumed by mechanical losses.

Is full of water in the pump at this time, if the long run, will lead to pump temperature rising, the pump shell, bearing will be fever, serious when can make the pump body thermal deformation, we called “stuffy head”, the head is big value, when gradually open the discharge valve, the flow rate will gradually increase, shaft power also slowly increase.

3. Flow-efficiency curve

Its curve is like a mountain. When the flow is zero, the efficiency is also zero. With the increase of the flow, the efficiency gradually increases.

-

Related products: Plastic magnetic pump / Beam Coupling